The Role of Round Balers in Straw Collection

Round balers play a crucial role in the efficient collection and handling of straw in modern agricultural practices. These machines are designed to compress loose straw into tightly packed, cylindrical bales, making storage, transportation, and utilization significantly more manageable. Their ability to produce uniform bales ensures consistency in size and density, which is essential for optimizing storage space and reducing spoilage.

One of the key advantages of round balers is their efficiency. They enable farmers to collect straw quickly, reducing the time and labor required compared to traditional methods. This efficiency is particularly beneficial during peak harvesting seasons when time is critical. Additionally, round balers are versatile and can handle various types of straw, including wheat, barley, and rye, making them indispensable across diverse farming systems.

Round bales also offer practical benefits. Their shape allows for easier handling and stacking, while their dense composition minimizes exposure to moisture and pests. Moreover, the technology integrated into modern round balers, such as moisture sensors and automatic tying systems, further enhances their functionality, ensuring high-quality bales with minimal effort.

Safety Precautions

Operating a round baler safely requires strict adherence to safety precautions to protect both the operator and others in the vicinity. The use of appropriate personal protective equipment (PPE) is essential. Operators should wear gloves to prevent hand injuries, safety glasses to protect eyes from debris, sturdy boots with non-slip soles to ensure proper footing, and hearing protection to mitigate the risk of hearing damage from prolonged exposure to machinery noise.

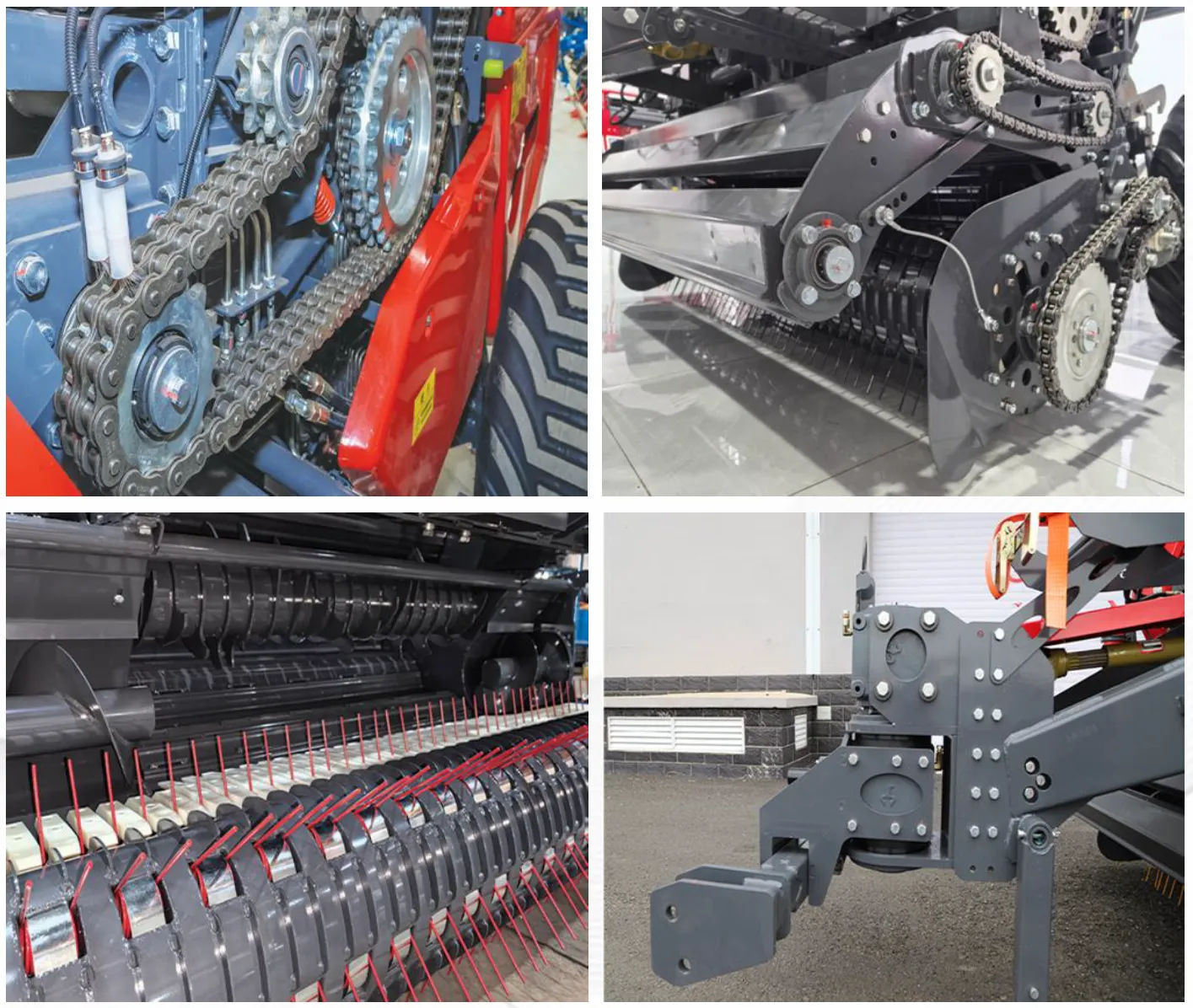

Machinery-specific risks must also be addressed to prevent accidents. Round balers have several moving parts, including belts, rollers, and pickup mechanisms, which pose significant entanglement hazards. Operators must stay clear of these components while the machine is in operation. Pinch points, where two parts move together, can cause severe injury if hands or clothing become caught. Hydraulic systems, which power many baler functions, present risks such as leaks or sudden movements, potentially leading to burns or crushing injuries.

Pre-operation checks are critical for safe operation. Inspect the machine thoroughly before use. Check for loose bolts, worn parts, or hydraulic leaks, and ensure that the tires are in good condition. Confirm that all guards and shields are securely in place, as these are designed to protect against moving parts and debris.

During operation, follow strict safety rules. Maintain a safe distance from the baler, ensuring no one stands near the discharge area. Avoid operating the baler on steep slopes, as this increases the risk of tipping. Never attempt to clear blockages, make repairs, or adjust settings while the machine is running, as this can lead to serious injury.

In case of emergencies, operators must know how to quickly shut down the tractor and disengage the baler. Familiarize yourself with the location and function of emergency shut-off controls. By following these precautions, the risks associated with round baler operation can be significantly minimized, ensuring a safer work environment.

Preparation Before Operation

Round Baler Step-by-Step Operation Guide

Step 1. Starting the Machine

To begin baling operations, start by engaging the tractor’s PTO (power take-off) at the manufacturer-recommended RPM to power the baler. Lower the pickup mechanism to the proper height, ensuring it lightly grazes the ground without dragging. Begin moving forward at a consistent speed, typically between 4-6 mph, to allow the baler to efficiently collect straw. A steady speed ensures uniform feeding into the chamber and reduces equipment strain or blockages. Always verify that all safety guards are in place before starting.

Step 2. Collecting Straw

Guide the baler along the windrows, ensuring the pickup mechanism gathers straw evenly without leaving material behind. Monitor the height of the pickup to avoid soil contamination or damage to the mechanism. Adjust the tractor’s direction as needed to stay centered on the windrows, ensuring consistent feeding. For uneven windrows or varying straw volumes, adapt your speed and positioning to avoid overloading the baler or creating uneven bales. Keeping the windrows clean and debris-free also helps maintain efficient operation.

Step 3. Bale Formation

As the baler collects straw, it feeds into the chamber, where it begins to rotate and form a tight core. Layers build progressively around the core until the bale reaches the desired size and density. Monitor the baler’s indicators, such as bale size gauges or fullness alarms, to track the progress of bale formation. Consistently check the chamber for even feeding, as uneven straw distribution may affect bale shape or integrity. Proper bale formation is critical for handling and storage efficiency.

Step 4. Wrapping and Binding

Once the bale reaches the target size, activate the netting or twine wrapping system. This can be done automatically or manually, depending on the baler model. Ensure the wrapping is secure and evenly distributed around the bale to maintain its shape during handling and storage. Proper wrapping prevents straw loss and minimizes exposure to moisture or pests. Regularly inspect the wrapping system for wear or clogs to avoid delays or poor results during operation.

Step 5. Ejecting the Bale

When the bale is fully wrapped, stop the tractor and use the hydraulic controls to raise the tailgate of the baler. Gently eject the bale onto the field, ensuring it lands without damage to the wrapping. Check that the bale has cleared the chamber completely before lowering the tailgate to resume baling. Always confirm that the area behind the baler is clear of obstructions or other workers before ejecting the bale. To optimize performance, handle turns smoothly to avoid disrupting windrows and adjust for varying straw volumes to maintain efficiency throughout the process.

Post-Operation Procedures and Maintenance

Proper shutdown and maintenance of a round baler are essential to ensuring its longevity, efficiency, and safe operation. After completing baling operations, follow a detailed shutdown process to prepare the equipment for storage or further use. Begin by disengaging the Power Take-Off (PTO) to stop the movement of internal components. Next, park the baler on level ground to ensure stability during cleaning and inspection. Remove any residual straw or debris from the machine, particularly around moving parts and critical areas, to prevent buildup, which could lead to mechanical issues or fire hazards.

For storage, it is crucial to protect both the baler and the bales it produces. Store bales in a dry, elevated area to reduce exposure to moisture and avoid spoilage. Ensure the baler itself is shielded from weather elements by parking it in a covered shelter or using a durable tarp. This prevents rust and deterioration caused by prolonged exposure to rain, snow, or sunlight.

Routine maintenance plays a vital role in keeping the baler in optimal condition. Perform daily cleaning after use to remove dust and debris. Conduct weekly inspections to check for wear on bearings, belts, and chains, and address any necessary adjustments or replacements. Seasonal maintenance should include overhauls such as replacing worn tines, lubricating all moving parts, and ensuring the pickup mechanism is in proper working condition.

Long-term care involves sharpening cutting components, such as knives, and regularly checking hydraulic fluid levels to maintain consistent performance. Proper maintenance not only extends the baler’s lifespan but also enhances reliability and ensures efficient operation during peak farming seasons.

Common Troubleshooting and Tips

1. Addressing Uneven Bales

Uneven bales are often caused by inconsistent tractor speed or irregular windrows during baling. To fix this, ensure a steady driving speed and create uniform windrows by raking before baling. Adjust the pickup height to suit the straw type, avoiding gaps or overfeeding. Regularly monitor the bale chamber to ensure even filling. Always consult the manual for proper settings tailored to your baler model.

2. Resolving Wrapping Failures

Wrapping failures, such as loose or incomplete twine binding, typically arise from low twine tension or worn twine threading components. First, check and tighten the twine tension according to the manual’s recommended levels. Inspect the twine path for obstructions or damage and replace worn parts promptly. Consider using high-quality twine compatible with your baler. Regular lubrication of working parts can further minimize failures in the wrapping process.

3. Clearing Blockages

Blockages often occur when baling wet or excessively dense straw. Stop the baler immediately to avoid damaging internal components. Manually remove the blockage while ensuring the baler is powered off and disengaged. Adjust the pickup tines to avoid overfeeding, and slow down the baling speed in damp conditions. For persistent issues, equip your baler with a crop cutter or pre-chopper to handle dense materials effectively.