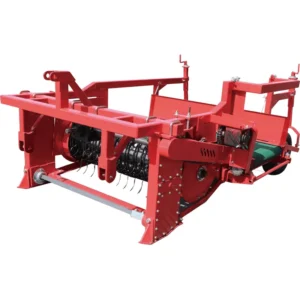

4BYH-2.6 Traktörler için Barbunya Hasat Makinesi

The 4BYH-2.6 kidney bean harvester is a specialized agricultural machine designed for efficient harvesting of kidney beans. It is a tractor-mounted puller that automates the extraction process, making it suitable for medium to large-scale farming operations. Engineered primarily in regions with high bean production, such as parts of Asia, this harvester addresses labor-intensive challenges by providing a mechanized solution that minimizes crop damage and maximizes yield recovery.

4BYH-2.6 Kidney Bean Harvester Overview

The 4BYH-2.6 kidney bean harvester is a specialized agricultural machine designed for efficient harvesting of kidney beans. It is a tractor-mounted puller that automates the extraction process, making it suitable for medium to large-scale farming operations. Engineered primarily in regions with high bean production, such as parts of Asia, this harvester addresses labor-intensive challenges by providing a mechanized solution that minimizes crop damage and maximizes yield recovery.

This model features a spring tooth picker mechanism for gentle uprooting of bean plants, ensuring minimal bruising to the pods. It includes mechanical sifters to separate beans from soil and debris, followed by collection into integrated bins. The design emphasizes durability with high-quality steel components resistant to field wear. It operates via a power take-off (PTO) system, drawing energy from the tractor for seamless integration.

In use, the harvester is attached to a tractor via a three-point linkage. As the tractor moves forward, the spring teeth penetrate the soil to pull up the bean plants. The machine then processes the harvest by shaking off excess dirt and conveying clean beans to storage. This process reduces manual labor significantly, allowing for consistent harvesting even in varying soil conditions.

Ürün Özellikleri

| HAYIR. | Öğe | Birim | Teknik Özellikler |

|---|---|---|---|

| 1 | Model Adı | / | 4BYH-2.6 Barbunya Hasat Makinesi |

| 2 | Bağlantı Tipi | / | Monte edilmiş |

| 3 | Teslim Alma Tipi | / | İlkbahar-tırnağı |

| 4 | Çalışma Genişliği | M | 2.6 |

| 5 | Eşleşen Güç Aralığı | kW | 66-88 |

| 6 | Çalışma Hızı Aralığı | km/sa | 6-10 |

| 7 | Genel Boyutlar (Uzunluk × Genişlik × Yükseklik) | mm | 2333×2870×1182 |

| 8 | PTO Hızı | r/dakika | 540 |

| 9 | Tekerlek İzi | mm | 2600 |

| 10 | Verimlilik | hm²/sa | 1.56-2.6 |

| 11 | Operatör Sayısı | kişi | 1 |

| 12 | Yapısal Ağırlık | kilogram | 1100 |

4BYH-2.6 Kidney Bean Harvester Features

1. Enhanced Harvesting Efficiency

The 4BYH-2.6 is designed for large-scale operations, significantly reducing the time and labor required for kidney bean harvesting. Its spring tooth picker mechanism allows for rapid and precise uprooting of plants, ensuring a high throughput rate. By automating the harvesting process, this machine can cover larger areas in less time, making it an ideal solution for farms with extensive bean cultivation.

2. Minimal Crop Damage

A standout feature of the 4BYH-2.6 is its gentle handling of crops. The spring tooth picker mechanism is engineered to carefully uproot bean plants without bruising or damaging the pods. This ensures a higher percentage of intact, market-ready beans, preserving quality and maximizing profits. Its careful design makes it particularly suitable for premium-grade bean production.

3. Effective Soil and Debris Separation

Equipped with advanced mechanical sifters, the harvester efficiently separates beans from soil, stones, and debris during the harvesting process. This eliminates the need for additional post-harvest cleaning, streamlining operations and reducing labor costs. The integrated system ensures that only clean beans are collected, saving both time and effort for farmers.

4. Dayanıklı ve Güvenilir Yapı

Built with high-quality steel components, the 4BYH-2.6 is designed for longevity and resistance to wear in demanding field conditions. Its robust construction ensures reliable performance season after season. Farmers can depend on the machine to operate effectively under varying soil and weather conditions, reducing the need for frequent repairs or replacements.

5. Seamless Tractor Integration

The harvester connects to tractors via a standard three-point linkage system and operates using the tractor’s power take-off (PTO). This seamless integration allows for easy setup and operation, ensuring compatibility with a wide range of tractors. Its user-friendly design minimizes downtime and simplifies maintenance, making it accessible even to operators with limited technical expertise.

6. Cost-Effective Farming Solution

By significantly reducing manual labor requirements and minimizing crop loss, the 4BYH-2.6 improves overall cost efficiency for farmers. Its ability to handle large-scale harvesting with consistent results lowers operational expenses while increasing yield recovery. Over time, its durable construction and reliable performance further enhance its value as a long-term investment for agricultural operations.

Uygulama Alanları

The 4BYH-2.6 kidney bean harvester is a versatile agricultural implement designed for use in a variety of farming environments, making it ideal for regions with medium to large-scale kidney bean production. Its primary application is in areas where labor shortages and the demand for efficient harvesting necessitate mechanized solutions. This harvester is particularly suited for agricultural zones with high kidney bean yields, such as parts of Asia, North America, and South America. It is commonly utilized in flat or gently sloping terrains, where its spring tooth picker mechanism can operate effectively without risk of soil erosion or uneven performance. Farmers in these regions benefit from the harvester's ability to handle diverse soil types, including sandy, loamy, and clay-rich soils, thanks to its robust construction and adaptable design.

Additionally, the 4BYH-2.6 is valuable for contract farming operations, where efficiency, speed, and consistent results are essential for meeting strict deadlines and production targets. Its capability to operate across varying soil and crop conditions makes it a preferred choice for large-scale farming cooperatives and agribusinesses. Furthermore, it is often employed in regions focusing on export-oriented kidney bean production, where maintaining the quality and integrity of harvested beans is crucial for meeting international market standards.

The machine also finds applications in sustainable farming practices, as it reduces the reliance on manual labor, optimizing resource use and lowering operational costs. By minimizing crop loss and damage, it ensures higher yield recovery, contributing to greater food security and profitability for farmers. Whether for family farms, cooperatives, or industrial-scale operations, the 4BYH-2.6 kidney bean harvester is a reliable and efficient tool that supports modern agricultural practices and promotes economic and environmental sustainability in diverse farming environments.

Common Troubleshooting of Kidney Bean Harvesters

1. Inconsistent Uprooting of Plants

If the harvester fails to uproot plants evenly, it may be due to improper adjustment of the spring tooth picker mechanism. Check the depth settings to ensure the teeth adequately penetrate the soil. Additionally, inspect for worn or damaged teeth, which can affect performance. Regular maintenance and calibration are crucial for consistent uprooting, especially when working in fields with varying soil conditions.

2. Excessive Crop Damage

Bruising or breaking of kidney bean pods often results from misaligned or overly aggressive picker mechanisms. Ensure the spring teeth are properly spaced and set to the appropriate tension to handle the plants gently. Inspect the sifting and conveying systems for signs of excessive vibration or impact, which could harm the beans during processing.

3. Poor Soil and Debris Separation

If soil or debris is not effectively separated from the beans, the mechanical sifters may be clogged or improperly adjusted. Clean the sifters regularly to prevent blockages and inspect for worn-out components. Ensure the separator is operating at the correct speed and that the vibration levels are optimized for the specific soil type in use.

4. Frequent Component Wear or Breakage

High wear on components like the picker teeth, sifters, or belts can result from operating the harvester in overly rocky or abrasive soil. Regularly inspect and replace worn parts to maintain efficiency. Using high-quality replacement components and avoiding excessively harsh field conditions can extend the lifespan of the machine.

5. Power Take-Off (PTO) Connection Issues

If the tractor’s PTO fails to drive the harvester effectively, check for misalignment or loose connections in the three-point linkage system. Inspect the PTO shaft for damage or wear and ensure it is properly lubricated. Verify that the tractor’s power output matches the harvester’s requirements to prevent operational inefficiencies.

6. Reduced Harvesting Efficiency

A decrease in harvesting speed or effectiveness may be caused by improper maintenance, such as dirty or clogged components. Clean the machine thoroughly after each use to remove residual soil and debris. Ensure all moving parts, including bearings and belts, are well-lubricated and aligned. Regular inspections and preventive maintenance schedules help sustain optimal performance.

Sıkça Sorulan Sorular

Q: What is the 4BYH-2.6 Kidney Bean Harvester?

A: This machine is a specialized tractor-mounted puller designed for harvesting kidney beans through a spring-tine mechanism that uproots plants gently. It incorporates sifters for separating beans from soil and debris, ensuring efficient collection into bins. Primarily used in commercial agriculture, it enhances productivity by automating labor-intensive tasks, with robust steel construction for durability in field conditions.

Q: What tractors are compatible with the 4BYH-2.6?

A: The harvester is compatible with tractors rated between 66-88 kW, or approximately 88-118 horsepower, utilizing a power take-off system at 540 r/min and a three-point linkage for attachment. This compatibility allows seamless integration with mid-range agricultural tractors commonly found in regions like North America and Asia, ensuring stable performance during operations.

Q: How does the 4BYH-2.6 operate?

A: Attached to a tractor, the machine advances at 6-10 km/h while spring teeth penetrate the soil to uproot bean plants. It then shakes off dirt via mechanical sifters and conveys clean beans to storage bins, requiring only one operator. This process minimizes manual intervention and adapts to varying field conditions for consistent results.

Q: What is the working width and row capacity?

A: The 4BYH-2.6 features a 2.6-meter working width, accommodating four rows of kidney beans simultaneously. This design enables efficient coverage of medium to large fields, reducing the number of passes needed and optimizing time management in commercial farming setups, as demonstrated in operational trials across diverse terrains.

Q: What is the productivity rate of the 4BYH-2.6?

A: It achieves a productivity rate of 1.56-2.6 hectares per hour, depending on field conditions and tractor speed. This high efficiency supports rapid harvesting on extensive plantations, leading to significant time savings and increased output for farmers, particularly in high-yield regions like Brazil and the United States.

Q: Is the 4BYH-2.6 suitable for different soil types?

A: Yes, it performs effectively on loamy, sandy, and even moderately humid soils due to its adjustable spring-tine mechanism and corrosion-resistant components. This adaptability ensures reliable operation in varied environments, such as arid areas in Egypt or fertile plains in India, minimizing downtime and maintaining harvest quality.

Q: What maintenance is required for the 4BYH-2.6?

A: Regular maintenance includes lubricating moving parts, inspecting spring tines for wear, and cleaning sifters after each use to prevent debris buildup. Annual checks on the PTO connection and structural integrity are recommended, ensuring longevity and safe operation, with manufacturer guidelines suggesting professional servicing every 500 hours of use.

Q: What are the dimensions and weight of the 4BYH-2.6?

A: The harvester measures 2333 mm in length, 2870 mm in width, and 1182 mm in height, with a total weight of 1100 kg. These compact yet sturdy dimensions facilitate easy transport and storage, while the weight distribution provides stability on uneven terrain during fieldwork.

Q: Where is the 4BYH-2.6 most commonly applied?

A: It is widely applied in commercial kidney bean farms in regions such as the United States, Egypt, Spain, India, and Brazil, where it addresses labor shortages and boosts efficiency. Its design suits sustainable practices, enabling precise harvesting in both organic and conventional systems for optimal yield management.

Müşteri Yorumları

Amerika Birleşik Devletleri Müşterisi:

"The 4BYH-2.6 Kidney Bean Harvester has been a game-changer for my farm. Its gentle harvesting mechanism ensures undamaged beans, which is critical for maintaining quality during processing. The floating intake header performs flawlessly on uneven terrain, reducing crop loss significantly. It’s durable, easy to maintain, and delivers excellent results season after season."

Avustralya Müşterisi:

"This harvester has made a noticeable difference on our farm. The 4BYH-2.6 handles the dry, hard soils of Australia with ease. Its robust design and efficient operation allow us to harvest quickly without worrying about breakdowns. The machine's reliability and low maintenance requirements have exceeded our expectations in every way."

Brezilya Müşterisi:

"The 4BYH-2.6 has been a fantastic tool for our large-scale bean fields. It works seamlessly in our tropical conditions and efficiently separates beans from pods. The fuel efficiency of the machine is remarkable, and the low rate of crop damage ensures a high-quality yield. I’m very pleased with its performance."

Fransa Müşterisi:

"In France, we appreciate precision and efficiency, and the 4BYH-2.6 delivers both. It maneuvers easily through our fields, even in tight spaces. The adjustable harvesting settings allow us to adapt to different bean varieties, ensuring minimal waste. It's a well-designed, efficient machine that has become essential for our operations."

Spain Customer:

"The 4BYH-2.6 Kidney Bean Harvester is a perfect fit for our diverse terrain. Its adjustable features make it versatile for different field conditions, and the low noise level is a pleasant surprise. The quality of harvested beans is excellent, and we’ve seen a noticeable boost in productivity since using it."

Almanya Müşterisi:

"This harvester is engineered with precision and efficiency, which aligns perfectly with German standards. The 4BYH-2.6’s robust construction ensures longevity, while its detailed control settings allow for minimal crop loss. It significantly reduces labor costs and operates smoothly even during extended harvesting periods. A highly reliable and professional-grade machine!"

Egypt Customer:

"In Egypt, we face challenging sandy soils and high temperatures, but the 4BYH-2.6 handles it brilliantly. The machine’s durability and ability to operate in harsh conditions are unmatched. Its gentle handling of crops ensures no damage, and the ease of maintenance makes it a dependable choice for the region."

Hollanda Müşterisi:

"Farmers in the Netherlands value efficiency and innovation, and this harvester delivers both. The 4BYH-2.6 performs exceptionally well on our wet, clay-heavy soils, and its advanced features reduce harvest time significantly. The clean, undamaged beans it produces meet our high-quality standards, making it an indispensable part of our farming."

Rusya Müşterisi:

"With Russia’s vast fields and extreme weather, the 4BYH-2.6 has proven to be a reliable partner. It handles large-scale harvesting efficiently, even under challenging conditions. The machine's sturdy build and high-capacity performance ensure that no beans are left behind. It’s a well-thought-out product designed for serious agricultural needs."