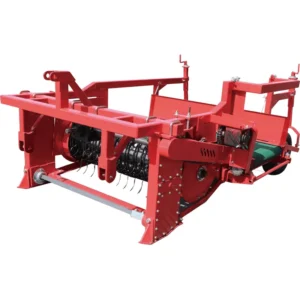

Комбайн для уборки фасоли 4BYQ-2.6 для тракторов

The 4BYQ-2.6 kidney bean harvester machine is a specialized agricultural implement designed for efficient harvesting of kidney beans, particularly suited for attachment to tractors in medium- to large-scale farming operations. This mounted-type machine features a four-ridge forward push mechanism that utilizes spring tooth pickers to gently extract kidney bean plants from the soil, minimizing damage to the roots and pods while adapting to various soil conditions. It is powered by a tractor with a matching power range of 66-88 kW and operates at a PTO speed of 540 r/min, achieving working speeds between 6-10 km/h.

4BYQ-2.6 Kidney Bean Harvester Overview

The 4BYQ-2.6 kidney bean harvester machine is a specialized agricultural implement designed for efficient harvesting of kidney beans, particularly suited for attachment to tractors in medium- to large-scale farming operations. This mounted-type machine features a four-ridge forward push mechanism that utilizes spring tooth pickers to gently extract kidney bean plants from the soil, minimizing damage to the roots and pods while adapting to various soil conditions. It is powered by a tractor with a matching power range of 66-88 kW and operates at a PTO speed of 540 r/min, achieving working speeds between 6-10 km/h.

In operation, the machine is hitched to the tractor and driven forward, where the forward push system lifts and collects the uprooted beans into a designated area, streamlining post-harvest processing. This design enhances bean quality by preventing excessive bruising or soil contamination, making it ideal for commercial farms, cooperatives, and organic producers. Benefits extend to improved efficiency, lower operational expenses, and reduced soil disturbance, supporting sustainable farming practices.

Технические характеристики изделия

| Нет. | Элемент | Единица | Технические характеристики |

|---|---|---|---|

| 1 | Название модели | / | 4BYQ-2.6 Kidney Bean Puller |

| 2 | Тип соединения | / | Установленный |

| 3 | Тип пикапа | / | Весенний ворс |

| 4 | Рабочая ширина | м | 2.6 |

| 5 | Диапазон согласованной мощности | кВт | 66–88 |

| 6 | Диапазон рабочих скоростей | км/ч | 6–10 |

| 7 | Габаритные размеры (Д×Ш×В) | мм | 2333×2870×1182 |

| 8 | Скорость ВОМ | об/мин | 540 |

| 9 | Колесная гусеница | мм | 2600 |

| 10 | Производительность | гм²/ч | 1.56–2.6 |

| 11 | Количество операторов | человек | 1 |

| 12 | Конструкционный вес | кг | 1100 |

Основные характеристики продукта

The 4BYQ-2.6 Kidney Bean Uprooting Machine offers numerous advantages that enhance agricultural productivity, particularly in kidney bean harvesting operations. Designed as a mounted-type implement for tractors with 66-88 kW power output, this machine employs a four-ridge forward push mechanism equipped with spring tooth pickers, enabling efficient uprooting at speeds of 6-10 km/h across a 2.6-meter working width. This configuration yields a productivity rate of 1.56-2.6 hm² per hour, allowing a single operator to cover extensive areas swiftly, thereby significantly outperforming manual harvesting methods in terms of time efficiency.

One primary benefit lies in its substantial reduction of labor requirements. Traditional kidney bean harvesting often demands large teams for manual pulling, which is physically demanding and time-intensive. In contrast, the 4BYQ-2.6 requires only one operator, alleviating the need for extensive workforce recruitment and training. This not only minimizes labor costs but also mitigates risks associated with labor shortages, enabling farmers to redirect human resources toward other critical farm activities, such as crop monitoring or processing.

From a cost-saving perspective, the machine's automation translates into lower operational expenses over time. By replacing manual labor with mechanical precision, it reduces overall harvesting expenditures, including wages and associated overheads. Its durable construction, featuring high-quality materials resistant to wear, ensures longevity with minimal maintenance needs—routine tasks such as cleaning, lubrication, and periodic inspections suffice to maintain optimal performance. This reliability is further supported by a three-year warranty and accessible after-sales service, providing long-term value and reducing downtime-related losses.

Efficiency is another cornerstone advantage. The forward push system gently extracts plants while minimizing soil disturbance, preserving soil structure and supporting sustainable farming practices. This approach also limits damage to beans and roots, resulting in higher-quality yields with reduced waste and contamination, which is particularly beneficial for organic producers and commercial farms aiming to maintain premium product standards. Adaptable to various soil conditions and kidney bean varieties, the machine's versatility extends its utility across small-scale, medium, and large operations.

Working Principle of Kidney Bean Harvester

The working principle of the 4BYQ-2.6 Kidney Bean Harvester is based on an advanced mechanism designed to ensure efficient, gentle, and precise harvesting of kidney beans. This harvester operates as a tractor-mounted implement, utilizing a combination of mechanical and structural components to extract kidney bean plants with minimal damage and high efficiency.

When the machine is attached to a tractor with a power range of 66-88 kW and a PTO speed of 540 r/min, the tractor provides the necessary power to drive the harvester. As the tractor moves forward at a working speed of 6-10 km/h, the four-ridge forward push mechanism comes into action. This mechanism, equipped with spring tooth pickers, gently penetrates the soil along the planted rows. The spring teeth are specifically designed to lift the kidney bean plants carefully, ensuring their roots and pods remain intact. This mechanism minimizes damage to the beans while preventing significant soil disturbance.

Once the kidney bean plants are uprooted, they are collected into a designated area by the forward push system. This streamlined process enables quick and organized collection, reducing the need for additional manual labor during post-harvest processing. The harvester’s mechanism also helps in separating the plants from excessive soil, ensuring cleaner output and improved bean quality.

The 4BYQ-2.6's design further adapts to various soil conditions, making it suitable for different farming environments. By minimizing soil disruption and maximizing pod preservation, the machine not only enhances productivity but also supports sustainable farming practices. Its efficient, automated operation reduces labor costs, increases harvesting speed, and ensures a consistent, high-quality harvest, making it an essential tool for modern agricultural enterprises.

Agricultural Gearbox and Kidney Bean Harvester

The agricultural gearbox plays a vital role in the efficient functioning of a kidney bean harvester, such as the kidney bean harvester. As a critical power transmission component, the gearbox ensures that the harvester operates smoothly and reliably by transferring power from the tractor’s engine to the harvester’s working mechanisms. It is specifically designed to handle the high torque and variable speeds required in agricultural machinery, making it an essential part of the harvesting process.

In the case of the kidney bean harvester, the agricultural gearbox is responsible for converting the tractor’s power output, typically in the range of 66-88 kW, into the precise mechanical movements needed for the forward push mechanism and spring tooth pickers. Operating at a PTO speed of 540 r/min, the gearbox ensures that this rotational power is transmitted efficiently to the harvester’s components, allowing it to maintain an optimal working speed of 6-10 km/h. This precise power transmission enables the harvester to perform critical tasks such as soil penetration, plant uprooting, and bean collection without excessive energy loss or mechanical strain.

The gearbox also contributes to the adaptability of the harvester in varying soil conditions. By providing consistent torque and controlled speeds, it ensures that the spring tooth pickers can operate effectively, even in compacted or irregular soil. Additionally, the gearbox’s robust design enhances the durability and longevity of the harvester, reducing maintenance requirements and downtime.

The agricultural gearbox is an indispensable component of the kidney bean harvester, enabling seamless power transmission, efficient operation, and versatility. Its integration into the 4BYQ-2.6 ensures high productivity, lower operational costs, and reliable performance in diverse farming conditions, making it an essential element for modern agricultural machinery.

Часто задаваемые вопросы

Q: What is the power requirement for the 4BYQ-2.6 Kidney Bean Harvester?

A: The harvester requires a tractor with a power range of 66-88 kW. This ensures sufficient energy to drive the spring tooth pickers and forward push mechanism effectively while operating at an optimal PTO speed of 540 r/min, maximizing efficiency and productivity.

Q: What is the working speed of the harvester?

A: The machine operates at a working speed of 6-10 km/h, allowing it to cover large areas efficiently. This speed strikes a balance between productivity and precision, ensuring kidney bean plants are gently uprooted and collected without compromising quality or causing excessive soil disturbance.

Q: What is the productivity range of the harvester?

A: The 4BYQ-2.6 achieves a productivity range of 1.56 to 2.6 hectares per hour. This high level of efficiency significantly reduces the time and labor required for harvesting kidney beans, making it an ideal choice for medium- to large-scale farming operations.

Q: What are the dimensions and weight of the harvester?

A: The harvester has compact dimensions of 2333 mm × 2870 mm × 1182 mm and a structural mass of 1100 kg. This design ensures easy attachment to the tractor, stable operation in the field, and convenient storage while maintaining durability and reliability.

Q: How does the forward push mechanism work?

A: The four-ridge forward push mechanism utilizes spring tooth pickers to carefully uproot kidney bean plants. This system ensures minimal damage to roots and pods while efficiently collecting the plants in a designated area for post-harvest processing, maintaining bean quality.

Q: How does the harvester adapt to different soil conditions?

A: The harvester’s spring tooth pickers and forward push mechanism are designed to handle various soil types, including compact, loose, or uneven terrains. This adaptability ensures consistent performance and reduces the risk of mechanical strain or inefficiency during operation.

Q: What are the benefits of using the harvester over manual methods?

A: The 4BYQ-2.6 significantly reduces labor costs by requiring only one operator. Its high-speed operation and productivity minimize the time needed for harvesting, while its gentle handling of plants ensures better bean quality compared to manual harvesting.

Q: Is the harvester easy to operate and maintain?

A: Yes, the machine features a user-friendly design for quick attachment to the tractor and straightforward controls for operation. Its robust construction and high-quality components make maintenance simple and infrequent, ensuring long-term reliability and reduced downtime.

Q: How does the harvester ensure high bean quality?

A: The machine’s gentle uprooting process and efficient collection system minimize bruising, pod damage, and soil contamination. This ensures that the harvested beans are of high quality, meeting the requirements of commercial, organic, and export-grade standards.

Отзывы покупателей

Клиент из США:

“The 4BYQ-2.6 Kidney Bean Harvester has been a game-changer for my farm. Its gentle harvesting mechanism ensures that my beans are undamaged, which is crucial for processing. The floating intake header works perfectly on uneven terrain, and I’ve seen a significant reduction in crop loss. An excellent investment!”

Клиент из Нидерландов:

“The 4BYQ-2.6 has been a fantastic purchase for our farm. Its precision and efficiency are unmatched, and the ease of operation has been a major plus for us. I’ve also noticed how sustainable it is, thanks to its minimal soil disturbance. It aligns perfectly with our eco-friendly practices.”

Российский клиент:

“Farming in Russia comes with unique challenges, especially with heavy soils, but this harvester has exceeded my expectations. It handles tough conditions with ease and delivers top-notch results. The time saved during the harvest alone has been incredible, and the bean quality is always excellent.”

Клиент из Индии:

“In India, where labor costs can be high during peak seasons, the 4BYQ-2.6 has made a huge difference. Its productivity and ability to work seamlessly across different soil types have been amazing. The gentle uprooting process ensures no wastage, and our harvest quality has never been better.”

Клиент из Австралии:

“This machine has saved us so much time and effort during the harvest season. The simplicity of attaching it to our tractor and its reliable performance across different soil conditions make it indispensable. I was particularly impressed with how it minimizes soil disruption while maintaining high-quality beans.”

Клиент из Бразилии:

“The 4BYQ-2.6 is perfect for large-scale operations like ours. We’ve seen a huge improvement in productivity, harvesting up to 2.6 hectares per hour with just one operator. The gentle lifting mechanism ensures our beans remain in excellent condition, which has improved our profit margins significantly.”

Клиент из Франции:

“I love how efficient and precise this harvester is. It works beautifully with our organic kidney bean crops, handling them delicately while maintaining speed. The reduced labor costs and consistent performance make it a great addition to our farm. It’s a machine we now can’t do without.”

Клиент из Германии:

“The 4BYQ-2.6 is built for durability and efficiency, which is exactly what farmers in Germany need. It performs exceptionally well even in challenging soil conditions, and its robust construction ensures low maintenance. It’s reliable, productive, and easy to operate—one of the best machines we’ve purchased.”

Клиент из Канады:

“This harvester has transformed how we manage our kidney bean harvests. The machine’s ability to adapt to uneven or compact soil is outstanding. I was impressed with the high-quality output and how it prevents bruising or damage to the pods. It’s worth every penny we spent.”

Детали

| Под редакцией | Yjx |

|---|