What Is the Main Function of the Round Baler?

Round Baler Structural Components

1. Pickup System

The pickup system is a critical component responsible for gathering loose hay or straw from the ground and feeding it into the baler. It consists of rotating tines or teeth that lift materials efficiently without leaving significant residue. The height of the pickup can typically be adjusted to match different crop conditions, ensuring optimal material collection. Proper maintenance, such as inspecting and replacing worn tines, is essential for smooth operation and minimizing material loss during the baling process.

2. Belts and Rollers

Belts and rollers are integral to forming the cylindrical shape of the bale. The belts rotate continuously within the baling chamber, compressing the material into a dense, uniform roll. High-tension belts provide the necessary pressure to achieve desired bale density. Rollers, often made of steel, guide and support the belts during operation. Regular inspection of belt tension and alignment is crucial to avoid slippage or uneven bales.

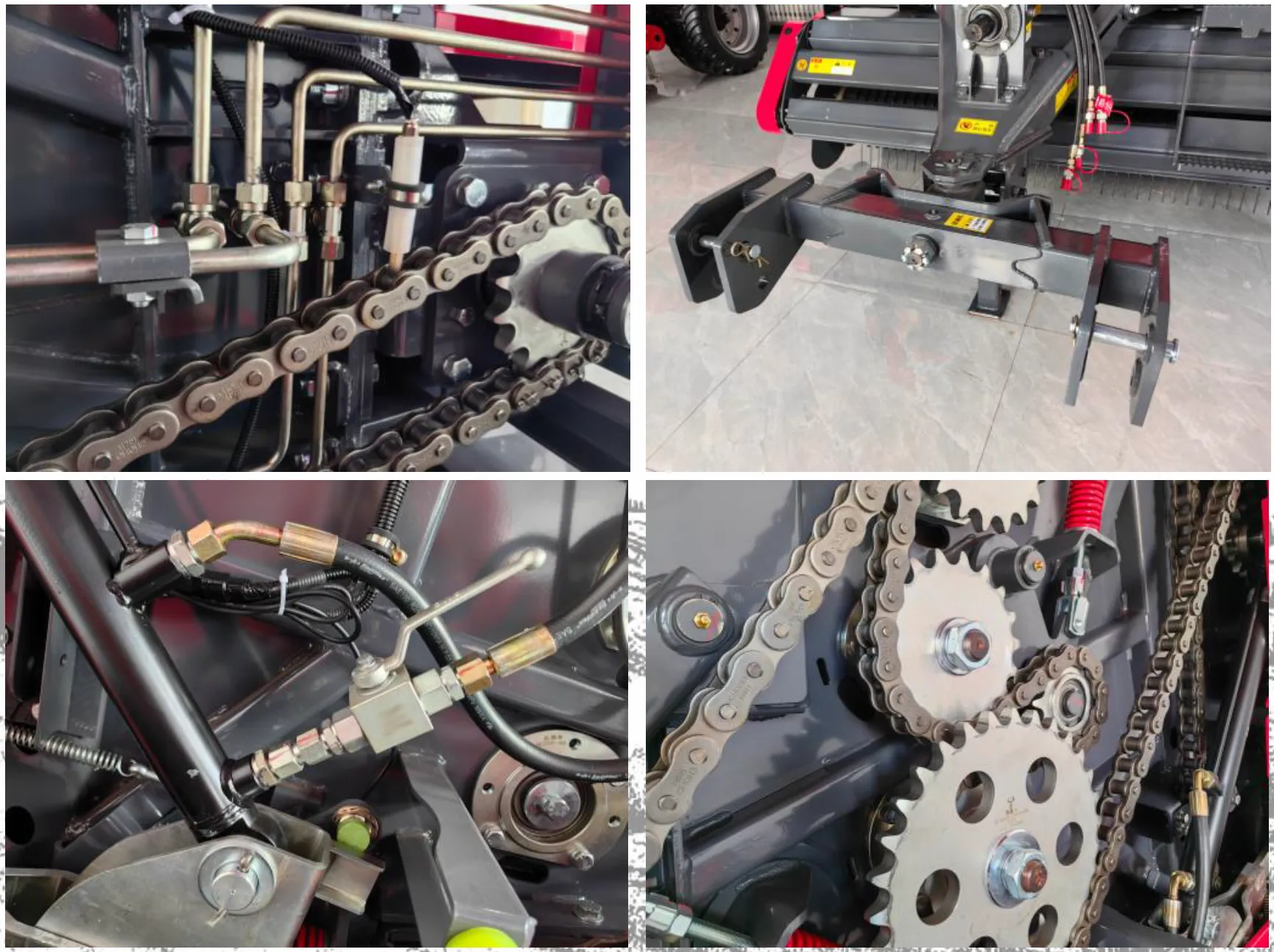

3. Chains and Drive Mechanism

Chains and sprockets form the drive mechanism that powers the baler’s moving parts, including the pickup, belts, and rollers. These chains transfer power from the tractor’s PTO (Power Take-Off) to the internal components. Proper lubrication and tension adjustments are necessary to prevent excessive wear or chain breakage. High-quality, durable chains are essential for ensuring long-lasting performance and minimizing downtime.

4. Hydraulic System

The hydraulic system is central to operating key functions such as opening and closing the tailgate, tensioning the belts, and ejecting the formed bales. Hydraulic cylinders generate the force required for these high-pressure tasks, ensuring precise control and efficiency. Periodic inspection of hydraulic lines, cylinders, and fluid levels is necessary to avoid leaks or performance issues. A well-maintained hydraulic system enhances operational reliability and reduces the risk of mechanical failure during baling.

The Importance of Regular Maintenance

Proper maintenance of round balers is essential for extending the machine’s lifespan, minimizing downtime during critical harvest periods, and enhancing operational safety. Regular upkeep ensures that all mechanical components, including belts, chains, rollers, and hydraulics, function efficiently. By addressing wear and tear promptly, farmers can prevent catastrophic failures, such as broken belts or hydraulic leaks, that could disrupt operations at peak times. This reliability is particularly crucial during harvest, where delays can lead to crop spoilage or losses.

From an economic perspective, consistent maintenance translates into significant cost savings. Well-maintained machinery operates more efficiently, resulting in lower fuel consumption. According to studies by the American Society of Agricultural and Biological Engineers (ASABE), efficient baling can reduce fuel usage by up to 10%, which is particularly important given rising fuel costs. Furthermore, keeping components like belts, chains, and bearings in good condition reduces the frequency of part replacements, saving on repair costs. Preventative maintenance also avoids costly emergency repairs that can be much more expensive than routine servicing.

Environmental and sustainability considerations further highlight the importance of maintenance. Preventing hydraulic oil leaks, for example, is critical to avoiding soil and water contamination, which can harm local ecosystems. Additionally, ensuring the baler operates efficiently reduces greenhouse gas emissions associated with unnecessary fuel consumption. A well-maintained machine also reduces material waste by producing uniform, dense bales, which are easier to store and transport.

Neglecting regular maintenance poses serious risks. Belt failures can lead to uneven bales, making storage and transport inefficient. Hydraulic system issues, such as leaks or pressure drops, can result in operational hazards, including bale ejection failures or even accidents. These problems not only compromise productivity but also jeopardize operator safety. Regular inspections, lubrication, and adherence to the manufacturer’s maintenance schedule are vital to ensuring the round baler operates safely, efficiently, and sustainably.

Daily Maintenance Checklist

1. Visual Inspection

Conduct a thorough visual inspection of the baler before and after use. Examine belts, chains, rollers, and the pickup mechanism for signs of wear, cracks, or loose components. Look for frayed belts, damaged chains, or bent tines in the pickup system, as these can compromise performance. Ensure all fasteners and bolts are tight to prevent operational failures during baling. Early detection of wear and damage can save time and costly repairs.

2. Cleaning Procedures

Remove all crop residue, dirt, and debris from the baling chamber, knotters (if applicable), and the exterior. Blockages and accumulated debris can lead to inefficiency and overheating, while dirt buildup on knotters can interfere with the wrapping mechanism. Pay special attention to areas prone to moisture retention, as this can cause corrosion over time. A clean baler not only operates more efficiently but also lasts longer.

3. Lubrication and Fluid Checks

Grease all fittings daily to ensure smooth operation of moving parts such as chains, rollers, and bearings. Check hydraulic fluid levels and inspect hoses and connections for leaks, cracks, or wear. Proper lubrication minimizes friction, reduces wear, and prevents costly mechanical failures. Address any leaks immediately to avoid hydraulic pressure loss or environmental contamination.

4. Operational Tests

Before and after use, verify the alignment of the PTO shaft to avoid power transfer issues. Check belt tension to ensure proper bale formation and inspect tire pressure for safe and stable operation in the field. Confirm that all guards, shields, and safety mechanisms are securely in place and functioning correctly to protect the operator during baling.

5. Post-Use Routines

After completing daily operations, clear any remaining material from the baler, especially in the chamber and pickup areas. Store the baler in a dry, sheltered location to protect it from moisture and weather exposure. Proper storage prevents rust and prolongs the lifespan of belts, chains, and other critical components, ensuring the baler is ready for the next use.

Weekly and Monthly Maintenance Tasks

1. Belt and Chain Inspections

Examine belts and chains for proper tension, alignment, and wear. Loose or misaligned belts may result in uneven bale formation, while worn chains can lead to inefficient power transfer. Adjust tension according to the manufacturer’s specifications and replace components showing excessive wear or damage. Regular assessment ensures consistent bale density, reduces downtime, and prevents costly failures during peak operation periods.

2. Hydraulic System Review

Inspect hydraulic cylinders, valves, and filters for leaks, cracks, or other signs of damage. Ensure all fittings are secure and replace hydraulic fluid if contamination is detected, as dirty fluid can degrade system performance and cause long-term damage. Clean or replace filters to maintain optimal pressure and prevent malfunctions. A well-maintained hydraulic system ensures safe and efficient operation.

3. Drive Components Maintenance

Check bearings, sprockets, and gearboxes for unusual noise, excessive heat, or vibration, which may indicate wear or misalignment. Lubricate these components as per the manufacturer’s recommendations to reduce friction and extend their lifespan. Promptly replace any damaged parts to prevent further mechanical issues. Regular maintenance of drive components ensures reliable power transmission and minimizes operational disruptions.

4. Electrical and Sensor Checks

Test electrical systems, including bale monitors, lights, and automated controls, to confirm proper functionality. Clean sensors to prevent false readings that could affect bale size or density. Replace faulty wires or connectors to avoid power failures or inaccurate data. Ensuring the proper functioning of electrical and sensor systems enhances precision and reduces errors during baling.

5. Documentation and Recordkeeping

Maintain a detailed log of all inspections, adjustments, and replacements. Documenting maintenance activities helps identify wear patterns, anticipate future repairs, and schedule preventative measures. This proactive approach minimizes unexpected breakdowns, optimizes machine performance, and allows for better budgeting of maintenance costs over the baler’s lifespan.

Seasonal and Annual Maintenance

1. Pre-Season Preparation

Before the season begins, perform a comprehensive structural evaluation of the baler. Inspect the frame for cracks, check weld points for weaknesses, and assess the condition of axles and wheels. Calibrate bale size and density settings according to crop requirements, ensuring consistent performance. Tighten fasteners and verify that all components are aligned and in working order. This thorough check ensures the baler is ready for efficient operation when the season starts.

2. Off-Season Overhauls

After the harvest season, disassemble key areas of the baler for deep cleaning and inspection. Remove debris and residue from hard-to-reach areas to prevent corrosion. Replace worn or damaged parts, such as pickup tines, belts, and bearings, to prepare for the next season. Perform pressure tests on the hydraulic system to identify potential leaks or weaknesses, ensuring reliable performance for future use.

3. Storage Guidelines

Proper storage is essential for extending the lifespan of the baler during the off-season. Apply rust inhibitors to metal surfaces to prevent corrosion. Elevate the baler to protect the tires from flat spots or degradation, and ensure all moving parts are well-lubricated. Cover exposed components and store the machine in a dry, sheltered location to protect it from weather damage and moisture buildup.

4. Professional Servicing

Schedule an annual inspection with a dealer or certified technician for advanced diagnostics. Professional servicing can include alignment checks, gearbox inspections, and software updates for modern balers with precision technology. These detailed evaluations can identify issues that may not be visible during daily or routine maintenance, ensuring peak performance and avoiding major breakdowns.

5. Adaptation for Usage Intensity

Adjust maintenance schedules based on the baler’s annual workload. High-volume operations producing a large number of bales should include more frequent inspections and part replacements to prevent wear-related failures. For lower-volume use, extend the maintenance intervals slightly but always prioritize regular checks to ensure reliability and performance. Tailoring maintenance to usage intensity helps optimize efficiency and reduce long-term costs.