Empacadora redonda 9YG-1.25 para tractores

The 9YG-1.25 round baler for tractors is an agricultural machine designed to optimize the process of collecting and baling forage materials such as hay, straw, and silage. This round baler is particularly suitable for small to medium-scale farming operations and is widely used for efficiently managing crop residues and forage production. Its primary function is to gather loose agricultural materials and compress them into compact, cylindrical bales, which are easier to handle, store, and transport.

9YG-1.25 Round Baler Overview

The 9YG-1.25 round baler for tractors is an agricultural machine designed to optimize the process of collecting and baling forage materials such as hay, straw, and silage. This round baler is particularly suitable for small to medium-scale farming operations and is widely used for efficiently managing crop residues and forage production. Its primary function is to gather loose agricultural materials and compress them into compact, cylindrical bales, which are easier to handle, store, and transport.

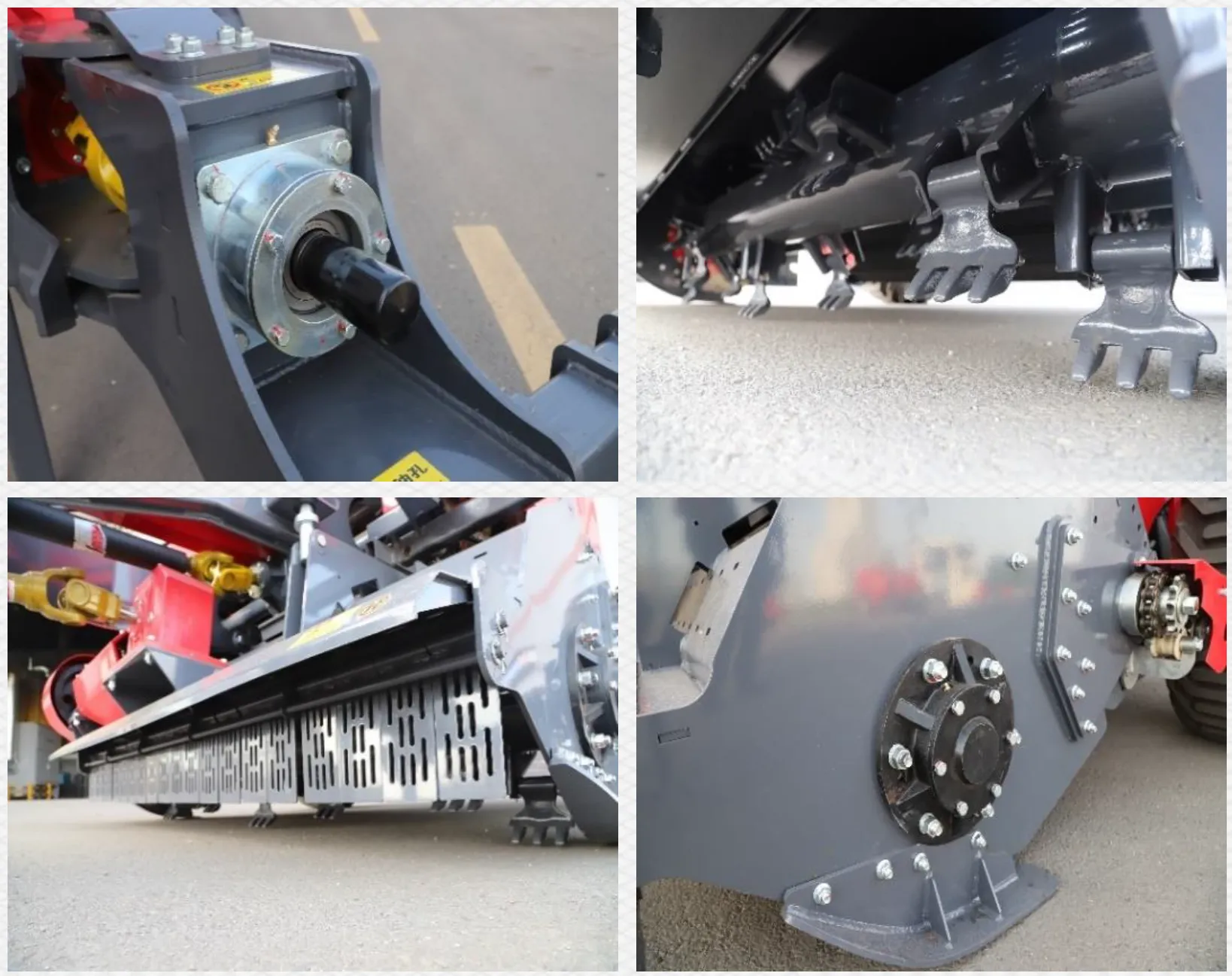

This model, the 9YG-1.25, is characterized by its compatibility with tractors, typically requiring a power take-off (PTO) connection to operate. It features a working width of approximately 1.25 meters, making it efficient in collecting forage over a considerable area with each pass. The baler is built with heavy-duty steel and robust components to ensure durability, even when operating in rugged or uneven terrains. Its compact design allows it to maneuver easily in tighter spaces, such as small fields or hilly landscapes.

The round baler is equipped with an advanced hydraulic or mechanical system that facilitates automatic bale wrapping using netting or twine. This ensures the bales are securely tied, preventing losses during transport or storage. Furthermore, the machine is designed to minimize forage loss during the baling process, preserving the nutritional value of the material.

Product Specifications

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | Empacadora redonda 9YG-1.25 |

| 2 | Hitching Method | / | Towed |

| 3 | Pickup Width | mm | 2240 |

| 4 | Pickup Structure Type | / | Spring Tooth and Hammer Claw Interchangeable |

| 5 | Feeder Structure Type | / | Auger + Tine and Roller Type |

| 6 | Compression Chamber Baling Mechanism Type | / | Drum Type |

| 7 | Compression Chamber Width | mm | 1250 |

| 8 | Compression Chamber Diameter | mm | 1200 |

| 9 | Number of Rolling Working Parts | pc | 18 |

| 10 | Rolling Drum Diameter | mm | 222 |

| 11 | Baling Method | / | Automatic Net Wrapping |

| 12 | Matching Power | kW/hp | ≧88.2/120 |

| 13 | Structural Mass | kg | 4558 |

| 14 | Power Take-off Shaft Speed | r/min | 720 |

| 15 | Overall Dimensions (L×W×H) | mm | 5250×2700×2350 (Working State) |

| 16 | Bale Density Control | / | Sensor Control |

| 17 | Bale Size (Diameter×Width) | mm | 1200×1250 |

| 18 | Bale Density | kg/m³ | 115-200 |

| 19 | Productivity | bales/h | 40-80 |

| 20 | Wheelbase | mm | 2450 |

| 21 | Operating Speed | km/h | 5-20 |

| 22 | Net Specification (Length×Width) | m | 2000×1.25/bale |

Product Advantages

The 9YG-1.25 Round Baler offers several significant advantages, particularly in its versatility and efficiency, making it an essential tool for modern agricultural operations. One of its standout features is its capability to achieve the interchangeability of the spring tooth picker and the hammer claw picker. This unique design allows the baler to adapt to different types of forage and crop residues, particularly excelling in handling standing corn stalks. By enabling the collection and baling of standing corn stalks directly, it eliminates the traditional need for pre-gathering the stalks into strips, thereby streamlining the entire process.

This innovative feature significantly reduces the operational steps and labor involved in stalk collection, leading to a noticeable reduction in overall operational costs. The ability to directly bale standing corn stalks not only saves time but also ensures higher efficiency by minimizing material loss during the collection process. Additionally, the machine's adaptability to different picker systems allows farmers to use it for a wide range of crops, including hay, silage, and straw, making it a highly versatile investment.

The 9YG-1.25 Round Baler is also designed for durability and reliability, with a robust structure capable of withstanding tough working conditions. Its advanced wrapping system ensures that bales are tightly packed and securely wrapped, reducing the risk of damage during transport or storage. Furthermore, the baler’s compact and streamlined design makes it easier to operate in fields of varying sizes, including those with narrow or uneven layouts.

By reducing labor requirements, increasing operational efficiency, and offering adaptability for multiple crop types, the 9YG-1.25 Round Baler provides an effective, cost-saving solution for forage and crop residue management. This makes it an indispensable tool for farmers seeking to optimize productivity while minimizing costs.

¿Cómo funciona una empacadora redonda?

A round baler is a highly efficient piece of agricultural equipment designed to streamline the process of collecting and baling hay, straw, or other crop residues into tightly packed, cylindrical bales. Its operation is based on a well-engineered system aimed at maximizing productivity in the field while ensuring consistent bale density and quality. The process can be broken down into three main steps:

Step 1: Forming the Core

As the machine moves through the field, the crop is gathered by the baler’s pickup system and fed into the forming chamber. Inside the chamber, belts or rollers immediately begin turning, shaping the collected material into a tightly packed core. This initial step is crucial to create a firm foundation for the bale, ensuring its structural integrity and making it easier to handle during transportation and storage.

Step 2: Layering and Compression

Once the hay enters the forming chamber, it is fed between the growing bale and the lower gate roll. As more material is added, it is compressed into smooth, dense layers. The baler’s system ensures even distribution of the crop across the surface of the bale, creating a uniform shape that prevents deformation and ensures efficient wrapping or netting.

Step 3: Maintaining Bale Density

As the bale continues to grow, the idler arm inside the baler rises. This movement forces oil from the connected hydraulic cylinder through a pressure-relief valve. This process ensures consistent pressure within the chamber, maintaining uniform bale density throughout the shaping process. The result is a compact, high-quality bale that is easier to handle, store, and transport.

The round baler's advanced design allows operators to achieve faster hay pickup and improved overall baling speed, making it an indispensable tool for modern farming operations.

How to Choose the Right Round Hay Baler?

Choosing the right round hay baler is essential for ensuring efficient operation, cost-effectiveness, and high-quality results. Here are some key factors to consider when selecting a round hay baler:

1. Bale Size and Density Requirements

Different balers produce bales of various sizes and densities, so it’s important to match the baler to your specific needs. Consider the storage space available, transportation methods, and the intended use of the bales. Larger and denser bales are ideal for commercial operations, while smaller bales may be more manageable for smaller farms.

2. Crop Type Compatibility

Not all balers are designed to handle every type of crop. Some models are better suited for hay, while others excel at baling straw, corn stalks, or silage. Ensure the baler you choose is compatible with the crop types you plan to harvest to avoid operational inefficiencies or damage to the machine.

3. Tractor Compatibility

Check the power requirements of the baler and ensure your tractor’s horsepower and hydraulic capacity meet or exceed the specifications. Mismatched equipment can lead to operational delays, increased wear and tear, or even equipment failure, impacting productivity.

4. Durability and Build Quality

The baler should be constructed with high-quality materials to withstand heavy use and tough agricultural conditions. Look for features like corrosion-resistant coatings, heavy-duty components, and reinforced pick-up systems to ensure long-term reliability and minimal maintenance costs.

5. Ease of Use and Automation Features

Modern balers often come with features like automatic tying, bale density adjustment, and user-friendly control systems. These features can reduce the learning curve for operators and improve overall efficiency, saving time and labor during peak seasons.

FAQs

Q: What is the minimum tractor power required to operate the 9YG-1.25 Round Baler effectively?

A: The 9YG-1.25 Round Baler requires a tractor with at least 75 kW (approximately 100 horsepower) to ensure optimal performance during baling operations. This power threshold allows for efficient pickup, compression, and ejection of bales in various field conditions. Insufficient power may result in reduced bale density or operational inefficiencies, particularly when handling dense or wet forage materials. It is advisable to match the baler with tractors equipped with a compatible PTO system for seamless integration and to avoid strain on the equipment.

Q: What are the typical bale dimensions and weight produced by the 9YG-1.25?

A: Bales formed by the 9YG-1.25 typically measure 1.2 meters in diameter and 1.25 meters in width, with weights ranging from 300 to 500 kilograms depending on crop type and moisture levels. This design ensures compact, uniform bales that facilitate easy storage and transport. For dry hay, weights are generally lower, while silage bales can be heavier due to higher moisture content, promoting better preservation through anaerobic conditions.

Q: How does the 9YG-1.25 handle wet forage materials compared to other balers?

A: The 9YG-1.25 excels in processing wet materials like Italian Ryegrass or silage, thanks to its fixed chamber design and hydraulic compression system, which achieve higher densities than many belt balers. This reduces slippage and improves bale integrity in moist conditions, minimizing spoilage. Operators should monitor moisture levels to prevent blockages, ensuring the machine's robust tines and chains function smoothly for consistent results across varying weather scenarios.

Q: What maintenance procedures are recommended for the 9YG-1.25 to ensure longevity?

A: Regular maintenance includes daily greasing of accessible points, inspecting chains and belts for wear, and cleaning the pickup area to prevent debris buildup. Hydraulic fluid levels should be checked weekly, with filters replaced as per the manufacturer's schedule. Annual servicing by qualified technicians is essential to address potential issues like bearing replacements, thereby extending the baler's operational life and maintaining efficiency in demanding agricultural environments.

Q: What safety features are incorporated in the 9YG-1.25 Round Baler?

A: The baler includes overload protection mechanisms, enclosed drivelines to prevent entanglement, and automatic shutdown sensors for detecting imbalances or blockages. Operators must adhere to guidelines such as wearing protective gear and ensuring the tractor's stability on uneven terrain. These features comply with international safety standards, reducing risks during operation and promoting a secure working environment for farm personnel.

Q: What types of binding options are available for bales produced by the 9YG-1.25?

A: The 9YG-1.25 offers both net wrapping and twine binding systems, allowing users to select based on crop needs and storage requirements. Net wrapping provides faster operation and better bale shape retention, ideal for silage, while twine is cost-effective for dry hay. Advanced models may include adjustable settings for binding density, ensuring bales remain secure during handling and transport without compromising overall productivity.

Q: How does the operational speed of the 9YG-1.25 affect baling efficiency?

A: Optimal speeds range from 4 to 8 kilometers per hour, depending on field conditions and crop density, enabling the production of 20 to 30 bales per hour under ideal circumstances. Slower speeds are recommended for wet or uneven terrain to maintain bale quality, while higher speeds suit dry, flat fields. This flexibility enhances farm efficiency by balancing throughput with the need for uniform compression and minimal downtime.

Customer Reviews

United States Customer:

“The 9YG-1.25 Round Baler has transformed our hay operations on our Midwest farm. Its reliable fixed chamber produces consistently dense bales, even in humid conditions, and the easy maintenance has kept downtime minimal. We've baled over 5,000 units this season without major issues, making it a solid choice for large-scale production.”

Australia Customer:

“On our sheep station in New South Wales, the 9YG-1.25 handles dry grass and straw effortlessly, delivering tight bales that store well in our arid climate. The hydraulic system is robust, and after-sales support from the local dealer has been prompt, ensuring we stay operational during peak harvest times.”

Brazil Customer:

“In our soybean and forage fields in Mato Grosso, the 9YG-1.25 Round Baler excels at compressing silage with high efficiency. Its durable build withstands rough terrain, and the net wrapping option has reduced spoilage significantly. Excellent value for money, with reliable performance season after season.”

France Customer:

“For our dairy farm in Normandy, the 9YG-1.25 provides uniform bales of wet grass, preserving quality for winter feed. The machine's simple controls and quick ejection system save labor, and we've appreciated the manufacturer's responsive technical assistance for any minor adjustments needed.”

Germany Customer:

“Operating on our precision farm in Bavaria, the 9YG-1.25 Round Baler integrates well with our tractors, producing high-density hay bales that optimize storage. Its engineering is precise, with low wear on components, and the warranty service has been efficient, supporting our sustainable practices effectively.”

Canada Customer:

“In the prairies of Alberta, the 9YG-1.25 manages both alfalfa and timothy hay with ease, even in variable weather. The baler's sturdy frame and automatic features have boosted our output, and dealer support for parts has been outstanding, minimizing interruptions during busy baling periods.”

Netherlands Customer:

“On our intensive grassland in Zuid-Holland, the 9YG-1.25 Round Baler compresses silage tightly, aiding in efficient fermentation. Its compact design suits our smaller fields, and the after-sales team has provided timely maintenance advice, ensuring consistent reliability throughout the year.”

Russia Customer:

“For our vast wheat and forage lands in Siberia, the 9YG-1.25 withstands cold temperatures and heavy use, forming durable straw bales. The chain-driven mechanism is tough, and we've received excellent spare parts delivery, keeping our operations running smoothly in remote areas.”

India Customer:

“In our rice-wheat rotation farms in Punjab, the 9YG-1.25 Round Baler efficiently handles straw residues, creating compact bales for livestock feed. Its affordability and low fuel consumption fit our needs perfectly, with strong local service support enhancing its overall dependability.”

Información adicional

| Edited by | Yjx |

|---|