9FZ-2.0 Fingerradrechen für Traktoren

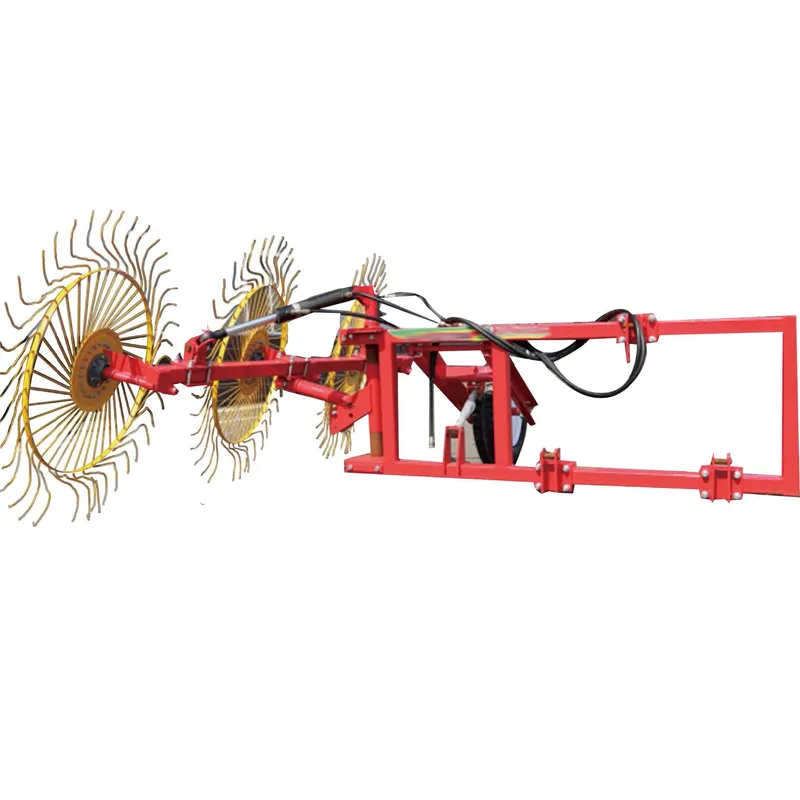

The 9FZ-2.0 finger wheel rake is a specialized agricultural implement designed to enhance efficiency in hay management operations. Primarily used for tedding, which involves spreading and aerating freshly cut hay to promote even drying, this machine attaches to tractors via a three-point hitch system. It features three rotating finger wheels, each with a diameter of 1500 mm and equipped with 40 durable steel tines, totaling 120 teeth across the unit. This configuration allows for a working width of 2 meters, enabling it to cover substantial ground while gently lifting and fluffing the hay without excessive damage to the crop.

9FZ-2.0 Finger Wheel Rake Overview

The 9FZ-2.0 finger wheel rake is a specialized agricultural implement designed to enhance efficiency in hay management operations. Primarily used for tedding, which involves spreading and aerating freshly cut hay to promote even drying, this machine attaches to tractors via a three-point hitch system. It features three rotating finger wheels, each with a diameter of 1500 mm and equipped with 40 durable steel tines, totaling 120 teeth across the unit. This configuration allows for a working width of 2 meters, enabling it to cover substantial ground while gently lifting and fluffing the hay without excessive damage to the crop.

Powered by tractors with a minimum of 25.73 kW (approximately 35 horsepower), the 9FZ-2.0 operates at speeds of 7-10 km/h, making it suitable for small to medium-sized farms. Its hydraulic folding mechanism facilitates easy transition between working and transport modes, with overall dimensions in operation measuring 3500×3500×1500 mm and a weight of 372 kg for stability and maneuverability. Constructed from high-quality materials, it adheres to industry standards such as JB/T17766-2011, ensuring reliability in various field conditions, including uneven terrain.

Key benefits include accelerated hay drying times, which reduce the risk of mold and nutrient loss, thereby preserving forage quality for livestock feed. The design minimizes soil contamination and crop loss compared to manual methods, while also lowering labor requirements. Maintenance is straightforward, involving regular inspections of tines, lubrication of moving parts, and hydraulic system checks.

Produktspezifikationen

| NEIN. | Artikel | Einheit | Spezifikationen |

|---|---|---|---|

| 1 | Product Name | / | 9FZ-2.0 Finger-wheel Tedder |

| 2 | Anbindemethode | / | Suspended Mounted Type |

| 3 | Folding Mechanism Type | / | Hydraulic Type |

| 4 | Number of Teeth | / | 120 (40 teeth/disk × 3 disks) |

| 5 | Number of Finger Wheels | / | (Note: Specification content missing) |

| 6 | Finger Wheel Diameter | mm | Φ1500 |

| 7 | Tedding Width | M | 2 |

| 8 | Passender Leistungsbereich | kW | ≥25.73 |

| 9 | Operating Speed Range | KM/H | 7-10 |

| 10 | Overall Dimensions (Length×Width×Height) in Working State | mm | 3500×3500×1500 |

| 11 | Machine Mass | kg | 372 |

| 12 | Product Execution Standard | / | JB/T17766-2011 |

9FZ-2.0 Finger Wheel Rake Advantages

1. Enhanced Hay Drying Efficiency

The 9FZ-2.0 finger wheel rake is specifically designed to promote faster and more even drying of freshly cut hay. Its three rotating finger wheels gently lift and fluff the hay, allowing for improved airflow and exposure to sunlight. This accelerates the drying process, reducing the likelihood of mold growth, preserving the hay’s nutritional value, and ensuring higher-quality forage for livestock feed.

2. Minimized Crop Damage and Soil Contamination

The rake’s durable steel tines are engineered to handle hay with care, reducing physical damage to the crop during operation. The gentle action of the tines prevents excessive tearing or crushing of the hay, while also minimizing soil disturbance. This results in cleaner forage with less contamination, which is critical for livestock health and feed quality.

3. Increased Productivity and Reduced Labor Requirements

With a working width of 2 meters and an operational speed of 7-10 km/h, the 9FZ-2.0 allows farmers to cover substantial ground in a shorter time. This mechanized approach significantly reduces the labor and time required compared to manual tedding, making it an ideal solution for small to medium-sized farms seeking to optimize efficiency.

4. Durability and Reliability in Various Field Conditions

Constructed from high-quality materials and adhering to industry standards like JB/T17766-2011, the 9FZ-2.0 is built to withstand demanding field conditions, including uneven terrain. Its robust design ensures long-lasting performance, maintaining consistent operation even in challenging environments. This durability translates to lower long-term costs and dependable results.

5. Hydraulic Folding for Easy Transition and Transport

The rake features a hydraulic folding mechanism that simplifies the transition between working and transport modes. Its compact design during transport ensures easy maneuverability, while the machine’s overall weight of 372 kg provides stability during operation. This convenience enhances usability for farmers, particularly when moving across different fields.

6. Low Maintenance and Easy Operation

Routine maintenance of the 9FZ-2.0 is straightforward, requiring simple inspections of the tines, regular lubrication of moving parts, and checks on the hydraulic system. This ease of upkeep reduces downtime and extends the machine’s lifespan. Combined with its user-friendly operation, the rake offers a hassle-free solution for efficient hay management.

|

|

|

|

Anwendungsgebiete

The 9FZ-2.0 Finger Wheel Rake is a versatile agricultural implement with broad applications in hay management, making it an essential tool for small to medium-sized farms. Its primary purpose is to assist in tedding operations, where freshly cut hay is spread and aerated to ensure even drying. This is particularly valuable in regions with high humidity or limited sunlight, where faster drying times are critical to prevent mold growth and preserve the nutritional quality of forage. The rake is also ideal for raking hay into windrows, which simplifies the baling process and improves the efficiency of subsequent operations. Farms focused on producing hay for livestock feed, particularly dairy or beef cattle, benefit greatly from the clean, uncontaminated forage that the 9FZ-2.0 helps produce.

The implement performs exceptionally well on a variety of terrain types, including uneven or sloped fields, due to its robust construction and reliable hydraulic folding mechanism. This adaptability ensures consistent performance across different field conditions, making it suitable for diverse farming environments. Additionally, the rake is compatible with tractors of at least 25.73 kW (35 horsepower), which are commonly found on small and mid-sized farms, further expanding its usability.

The 9FZ-2.0 can also be used in multi-crop farming operations where hay or straw management is required after harvesting crops like wheat, barley, or oats. By reducing soil contamination and crop loss, the rake ensures high-quality residue management, which is crucial for sustainable farming practices. Whether used in hay drying, windrowing, or residue collection, the 9FZ-2.0’s efficiency, durability, and ease of operation make it an indispensable tool for farmers aiming to improve productivity and forage quality while minimizing labor and time investments.

Wartungstipps für Fingerradrechen

1. Regular Inspection of Tines

The steel tines are critical to the rake’s performance, and regular inspections are essential to identify wear or damage. Check for bent, broken, or excessively worn tines after each use. Replace any damaged tines promptly to ensure consistent hay handling and avoid disruptions during operation.

2. Schmierung beweglicher Teile

The rake’s moving components, including the rotating finger wheels and hydraulic mechanisms, require regular lubrication to reduce friction and prevent premature wear. Use high-quality grease or oil as recommended by the manufacturer, and ensure all grease fittings are properly maintained. Lubrication should be conducted after every 8-10 hours of operation.

3. Hydraulic System Maintenance

The hydraulic folding mechanism is vital for transitioning between working and transport modes. Regularly inspect hydraulic hoses, fittings, and cylinders for leaks or damage. Ensure that the hydraulic fluid level is adequate and replace it as needed. Proper maintenance of the system ensures smooth and reliable operation.

4. Tire and Hitch Connection Checks

If the rake features tires or attaches to a tractor via a hitch, ensure these components are secure and in good condition. Check tire pressure and inspect for cuts or punctures that may compromise stability. Confirm that the three-point hitch is correctly aligned and tightly secured to the tractor.

5. Debris Removal After Use

After each operation, remove any accumulated hay, dirt, or debris from the rake. Pay special attention to the finger wheels and tines, as debris buildup can affect performance. Cleaning the rake thoroughly after use prevents rust and prolongs the lifespan of its components.

6. Seasonal Storage and Protection

When not in use, store the rake in a dry, covered area to protect it from weather-related damage. Apply a protective coating to exposed metal parts to prevent rust. Before long-term storage, inspect all components, lubricate moving parts, and cover hydraulic systems to maintain the rake’s readiness for the next season.

Häufig gestellte Fragen

Q: What is the primary function of the 9FZ-2.0 Finger Wheel Rake?

A: The 9FZ-2.0 is primarily designed for tedding hay, which involves spreading and aerating cut forage to accelerate drying; it attaches to tractors via a three-point hitch, utilizing three finger wheels to gently lift and fluff the crop, thereby enhancing drying efficiency and preserving nutritional quality in agricultural operations.

Q: What are the key specifications for compatibility with tractors?

A: This rake requires tractors with a minimum power output of 25.73 kW, equivalent to about 35 horsepower, and uses a standard three-point hitch system for secure attachment; it ensures stable performance across various tractor models, facilitating seamless integration into existing farm machinery setups without necessitating extensive modifications.

Q: How does the finger wheel design contribute to its effectiveness?

A: Equipped with three wheels each measuring 1500 mm in diameter and featuring 40 durable steel tines for a total of 120 teeth, the design allows for a 2-meter working width, enabling gentle yet thorough tedding that minimizes crop damage while effectively spreading hay on uneven terrain.

Q: What is the recommended operating speed for the 9FZ-2.0?

A: The optimal operating speed ranges from 7 to 10 km/h, which balances efficiency with crop preservation; this speed enables coverage of substantial areas, such as up to 2 hectares per hour, while reducing the risk of soil disturbance or excessive wear on the equipment during field use.

Q: How does the hydraulic folding mechanism work?

A: The hydraulic folding system allows easy transition between operational and transport modes by folding the wheels compactly; controlled via the tractor's hydraulics, it enhances maneuverability, with working dimensions of 3500×3500×1500 mm and a transport configuration that simplifies movement between fields or storage areas.

Q: What maintenance is required for long-term reliability?

A: Regular maintenance includes inspecting and replacing worn tines, lubricating moving parts such as wheel bearings, and checking the hydraulic system for leaks; adhering to these practices, as per JB/T17766-2011 standards, ensures durability in harsh conditions, extends equipment lifespan, and maintains optimal performance for consistent hay management.

Q: Is the 9FZ-2.0 suitable for different crop types?

A: Yes, it handles various crops, including alfalfa, grass, and clover effectively due to its adjustable tine pressure and gentle lifting action; this versatility supports diverse farming needs, reducing soil contamination and crop loss while promoting even drying across different forage types in varied environmental conditions.

Q: What is the weight and its impact on performance?

A: Weighing 372 kg, the rake provides sufficient stability for operation on uneven ground without excessive soil compaction; this balanced weight enhances traction and control when paired with compatible tractors, contributing to precise tedding and minimizing operational vibrations during extended use in the field.

Q: How does it improve hay quality compared to manual methods?

A: By automating the tedding process, it reduces drying time and prevents mold through uniform aeration, preserving nutrients better than labor-intensive manual raking; this results in higher-quality forage for livestock, lowers labor costs, and decreases the likelihood of weather-related spoilage in hay production cycles.

Kundenrezensionen

Kunde aus den Vereinigten Staaten:

“The 9FZ-2.0 Finger Wheel Rake is a game-changer for our farm. Its durability stands up to the tough conditions we face here in the Midwest. The rake’s precision in creating consistent windrows has reduced our baling time significantly. Easy maintenance and smooth operation make it an asset we can rely on year-round.”

Australischer Kunde:

“In the harsh and dry Australian climate, efficiency is key, and the 9FZ-2.0 Finger Wheel Rake excels. Its ability to handle large volumes of hay without clogging is impressive. The sturdy design ensures it withstands our rugged terrain, and its minimal downtime has increased our productivity during peak harvesting seasons.”

Kanadischer Kunde:

“With Canada’s unpredictable weather, we need equipment we can trust, and the 9FZ-2.0 Finger Wheel Rake doesn’t disappoint. Its ability to handle both wet and dry hay is remarkable. The rake’s sturdy structure and ease of adjustment save us valuable time, even during challenging conditions.”

Niederländischer Kunde:

“In the Netherlands, where precision and efficiency are paramount, the 9FZ-2.0 Finger Wheel Rake stands out. It ensures our windrows are clean and well-spaced, optimizing baling efficiency. The rake’s smooth operation and low maintenance requirements make it ideal for our high-paced dairy and hay production systems.”

Russischer Kunde:

“The 9FZ-2.0 Finger Wheel Rake performs exceptionally well in Russia’s tough agricultural conditions. Its heavy-duty construction can handle large fields and uneven terrain with ease. The rake’s ability to create uniform windrows even in dense crops has helped us improve productivity and reduce harvest losses.”

Indischer Kunde:

“In India’s diverse farming landscape, the 9FZ-2.0 Finger Wheel Rake proves its value. From handling hay to crop residues, it operates efficiently even in challenging conditions. Its easy-to-use design makes it accessible for all operators, and its reliability has made it a crucial tool for our farm’s success.”

Brasilianischer Kunde:

“Brazil’s diverse agricultural needs demand versatile machinery, and the 9FZ-2.0 Finger Wheel Rake fits perfectly. Whether handling hay or sugarcane straw, its performance is outstanding. We appreciate its minimal fuel consumption, low maintenance requirements, and consistent results, making it an essential part of our farm’s equipment.”

Französischer Kunde:

“French farmers take pride in efficiency and quality, and the 9FZ-2.0 Finger Wheel Rake meets these standards. It produces clean, uniform windrows that are perfect for baling. The rake’s quiet operation and hydraulic adjustments make it user-friendly, while its durability ensures it performs well season after season.”

Deutscher Kunde:

“German farms demand precision, and the 9FZ-2.0 Finger Wheel Rake delivers. Its ability to create evenly distributed windrows ensures maximum efficiency during baling. The rake’s robust construction and smooth hydraulic system make it reliable and easy to use. It has become an indispensable tool for our operation.”

Zusätzliche Informationen

| Herausgegeben von | Yjx |

|---|