مكبس بالات دائرية 9YG-2.24D (S9000) للجرارات

The 9YG-2.24D round baler S9000 series is the latest product developed specifically for agriculture and animal husbandry. It is mainly used for integrating and rolling the straw and forage of various crops such as corn, rice, wheat and soybeans into round bales after harvest. This round baler series of products adopts an “axial flow” semi-forced feeding mechanism and a camless and ring-free picking mechanism. Compared with the traditional ones, this mechanism not only reduces power consumption but also increases the feeding volume and reduces the probability of grass blockage and blockage, thereby increasing the operation efficiency by nearly double.

9YG-2.24D Round Baler (S9000) Overview

The 9YG-2.24D round baler S9000 series is the latest product developed specifically for agriculture and animal husbandry. It is mainly used for integrating and rolling the straw and forage of various crops such as corn, rice, wheat and soybeans into round bales after harvest. This round baler series of products adopts an "axial flow" semi-forced feeding mechanism and a camless and ring-free picking mechanism. Compared with the traditional ones, this mechanism not only reduces power consumption but also increases the feeding volume and reduces the probability of grass blockage and blockage, thereby increasing the operation efficiency by nearly double. This institution was independently developed and designed by our company and holds exclusive intellectual property rights.

مواصفات المنتج

| لا. | غرض | وحدة | مواصفة |

|---|---|---|---|

| 1 | اسم الطراز | / | مكبس بالات دائرية 9YG-2.24D (S9000) |

| 2 | طريقة الربط | / | تم سحبها |

| 3 | عرض الالتقاط | مم | 2240 |

| 4 | نوع هيكل الالتقاط | / | Tine type |

| 5 | نوع آلية التغذية | / | Fork and Roller Type |

| 6 | نوع آلية التغليف بالضغط | / | نوع الأسطوانة |

| 7 | عرض الضغط | مم | 1400 |

| 8 | قطر الانضغاط | مم | Φ 1200 |

| 9 | عدد أجزاء الضغط العاملة | الوحدات | 18 (Roller) |

| 10 | قطر بكرة الضغط | مم | Φ 222 |

| 11 | طريقة ربط البالات | / | Net Wrap |

| 12 | قوة المطابقة | كيلوواط | 55–100 |

| 13 | الكتلة الهيكلية | كيلوغرام | 4262 |

| 14 | سرعة عمود خرج الطاقة | دورة/دقيقة | 720 |

| 15 | Overall Dimensions (L × W × H) (Working State) | مم | 4240 × 3010 × 2450 |

| 16 | التحكم في كثافة البالات | / | التحكم بالحساس |

| 17 | أبعاد البالة (القطر × العرض) | مم | Φ 1300 × 1400 |

| 18 | كثافة البالة | كجم/م³ | 100–200 |

| 19 | إنتاجية | بالات/ساعة | 40–100 |

| 20 | قاعدة العجلات | مم | 2600 |

| 21 | سرعة العمل | Km/h | 5–35 |

| 22 | مواصفات غلاف الشبكة (الطول × العرض) | / | 2000 × 1.4 m/bale |

مزايا المنتج

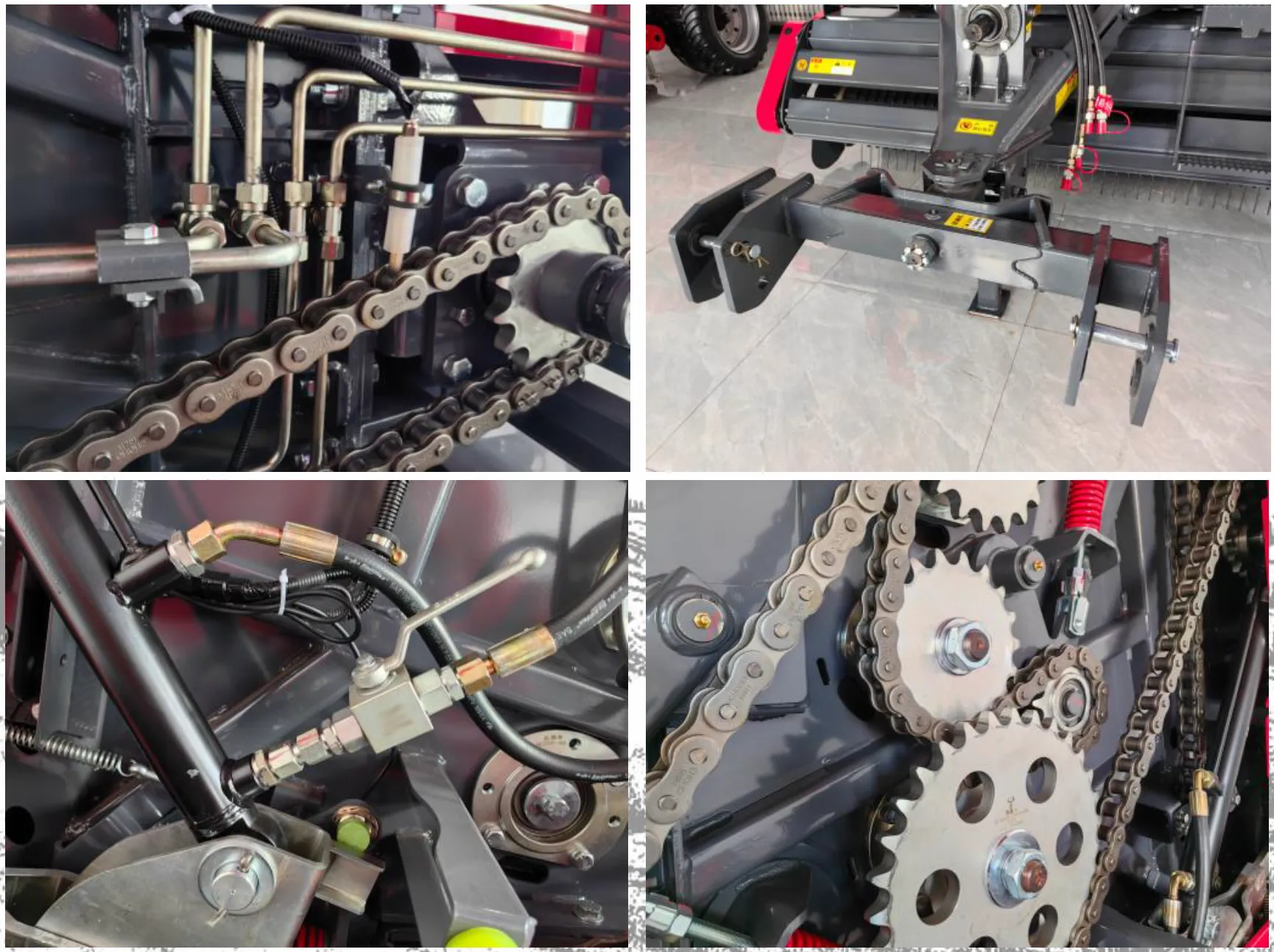

The rear bin is equipped with double-sided 20A heavy-duty chains, which increase the compression pressure. The density of the round bundles produced is greater, all reaching 500 to 1000 jin, meeting the customers' demands.

The new type of traction device has a maximum torque of 1000 Nm and the advantage of adjustable tilt Angle. The lateral steering Angle is 100, and the maximum limit Angle of the tractor's lateral tilt is 30°. This solves the problem that the existing room-drawn round baling machine's room-drawn device can only be adjusted in the horizontal direction within a certain range and cannot adjust the tilt Angle. Problems that seriously affect the effectiveness and progress of customers' work.

The electronic control system takes the SPC-SFMC-X2214A controller as its core and features a wide voltage input of 12 to 24VDC, vibration resistance, a wide temperature range, and high protection. The computer box in the cab communicates with the baler controller via CAN bus, ensuring stable and reliable communication. It is supplemented with injection-molded cables as the electrical connection between the tractor and the round baler. The overall wiring harness layout of the vehicle is simple and reliable.

Round Hay Baler Applications

1. Corn Straw Management

Round balers are highly efficient in compressing and forming corn straw into compact bales, making transportation and storage more convenient. This helps reduce waste in agricultural fields and promotes sustainable practices by repurposing corn residues into animal feed or bioenergy resources.

2. Rice Straw Utilization

The application of round balers in rice straw management mitigates the environmental impact of traditional straw burning. By baling rice straw, farmers can use it as raw material for biofuel production, livestock bedding, or even as compost, enhancing resource utilization and reducing pollution.

3. Wheat Straw Processing

Round balers are essential in collecting and compressing wheat straw after harvest. These compact bales are widely used in industries such as livestock feeding, mushroom cultivation, and eco-friendly packaging. Their uniform size simplifies handling, storage, and commercial distribution.

4. Soybean Straw Repurposing

Soybean straw, often overlooked, can be effectively baled using round balers. The bales are suitable for animal feed, soil mulching, and erosion control, ensuring maximum utilization of agricultural byproducts. This enhances farm efficiency and contributes to circular agricultural practices.

5. Forage Preservation

Round balers play a critical role in preserving forage crops like alfalfa and grasses. By creating tightly packed and weather-resistant bales, the quality and nutritional value of forage are retained for livestock feeding during off-seasons, ensuring year-round fodder availability.

|

|

Round Baler Troubleshooting: Common Issues and Solutions

1. Uneven Bale Formation

Uneven bales result from improper feeding of crop material or incorrect baler adjustments. Ensure consistent crop flow by maintaining an even windrow and inspecting the pickup and feeding mechanisms regularly. Adjust tension settings to achieve uniform bale density.

2. Twine or Net Wrap Issues

Twine or net wrap failures can occur if the wrapping mechanism is misaligned or if low-quality material is used. Regularly inspect and clean the wrapping system, use high-quality twine or net, and ensure proper threading to avoid issues.

3. Bale Chamber Blockages

Blockages in the bale chamber are often caused by overfeeding or wet crop material. To prevent this, monitor the crop moisture level, avoid exceeding the baler’s capacity, and clear debris from the chamber and rollers after every use.

4. Pickup Reel Jamming

The pickup reel may jam if foreign objects or excessive crop residue are present. Inspect the field for debris before baling and clean the pickup area frequently. Adjust the reel height to minimize contact with the ground or overly thick windrows.

5. Belt Slippage or Breakage

Worn or improperly tensioned belts can slip or break during operation. Check the belt tension regularly, replace frayed or damaged belts, and ensure proper alignment to prevent operational delays and ensure smooth baling performance.

6. Overheating of Hydraulic System

Round baler hydraulic systems can overheat due to prolonged use or insufficient fluid levels. Regularly inspect hydraulic fluid levels and quality, clean the cooling system, and avoid excessive strain on the baler by operating it within its recommended capacity.

الأسئلة الشائعة

Q: What is the optimal crop type for the 9YG-2.24D round baler?

A: The 9YG-2.24D is designed for handling a wide range of crops, including corn straw, rice straw, wheat straw, soybean straw, and forage. Its advanced baling mechanism ensures efficient performance with both dry and moderately moist crop materials.

Q: What is the recommended tractor horsepower for operating the 9YG-2.24D?

A: The 9YG-2.24D requires a tractor with a minimum power output of 50 horsepower. This ensures sufficient pulling and PTO power for smooth operation, even in fields with dense or heavy crop residues.

Q: How can I ensure uniform bale density with the 9YG-2.24D?

A: To achieve uniform bale density, maintain an even windrow during operation and adjust the baler’s tension settings according to the crop type. Regularly inspect the pickup mechanism and rollers for optimal material feeding and compaction.

Q: What should I do if the baler experiences a blockage?

A: Blockages can occur due to overfeeding or wet material. Stop the baler immediately, turn off the tractor PTO, and safely clear the blockage. To prevent future issues, monitor windrow size and avoid baling excessively wet crops.

Q: How often should the 9YG-2.24D be serviced?

A: Routine maintenance is essential for efficient performance. Inspect and lubricate all moving parts after every 8-10 hours of operation. Conduct a thorough inspection of belts, chains, and bearings every 100 hours, replacing worn components as needed.

Q: What type of net wrap or twine is compatible with the 9YG-2.24D?

A: The baler is compatible with standard agricultural-grade net wrap and twine. For optimal performance, use high-quality materials that match the specifications outlined in the user manual to ensure proper wrapping and bale integrity.

Q: Can the 9YG-2.24D handle wet or silage crops?

A: While the 9YG-2.24D is primarily designed for dry crops, it can handle moderately wet materials, such as silage, with proper adjustments. Ensure that the crop moisture level does not exceed recommended limits to avoid blockages or baling inefficiencies.

Q: What safety precautions should be followed during operation?

A: Before starting the baler, ensure all safety guards are in place and check for loose components. Always disengage the tractor PTO and turn off the engine before performing maintenance or clearing blockages. Follow all safety guidelines in the user manual.

Q: What are the key troubleshooting steps for common issues?

A: For uneven bales, inspect and adjust the tension and pickup mechanisms. If twine or net wrap fails, check alignment and threading. In case of belt slippage or hydraulic overheating, inspect fluid levels, belt tension, and cooling systems regularly.

Customer Reviews After Purchase

عميل من الولايات المتحدة:

“The 9YG-2.24D Round Baler has been a game-changer for our farm. Its ability to handle large volumes of hay and straw with consistent performance is remarkable. The dense, uniform bales make storage and transportation much easier. Maintenance is straightforward, and the machine is built to last. Even in wet conditions, the baler operates efficiently without clogging. It’s incredibly versatile, handling various crop types effortlessly. The intuitive controls make it user-friendly for operators of all skill levels. Fuel efficiency is another big plus, saving us money during long harvest days. Overall, it’s a reliable and high-performing baler we highly recommend.”

عميل أستراليا:

“Our farm operates in challenging conditions with high temperatures and dry fields, but the 9YG-2.24D Round Baler performs flawlessly. It picks up straw and grass efficiently, and the bales are dense and well-wrapped. Its reliability has drastically improved our productivity during the harvest season. The robust design ensures durability even on rough terrain. The easy-to-use interface saves us time during setup and operation. Maintenance is minimal, and the parts are readily available if needed. It’s clear this machine was designed with farmers’ needs in mind. We’ve seen a noticeable improvement in harvest efficiency since using this baler.”

عميل من ألمانيا:

“With the 9YG-2.24D Round Baler, we’ve seen a noticeable boost in productivity on our farm. The machine handles dense German grass effortlessly, producing uniform bales that are perfect for storage. Its robust design withstands continuous use without any mechanical issues. The baler is surprisingly quiet, which is a benefit when working near residential areas. The automatic wrapping system is quick and ensures secure bales every time. It performs exceptionally well even on uneven terrain. The energy efficiency is remarkable, reducing our overall operating costs. It’s clear this baler was built with German engineering standards in mind.”

عميل كندا:

“The 9YG-2.24D Round Baler is perfect for Canadian farms dealing with harsh weather conditions. It processes hay and straw quickly, producing bales that stay intact during storage and transportation. The sturdy frame withstands freezing temperatures and heavy use. The controls are intuitive, making it easy for new operators to learn. Its low maintenance requirements save us valuable time during the busy season. The machine’s efficiency has reduced fuel consumption significantly. We’ve been impressed by its ability to handle large volumes without compromising performance. It’s a dependable and high-quality baler that’s ideal for our farming needs.”

عميل من هولندا:

“The 9YG-2.24D Round Baler is ideal for our fields in the Netherlands. It produces bales that are consistent in size and density, which is vital for storage in limited spaces. The machine handles wet and dry grass efficiently without clogging. Its compact design makes it easy to maneuver in tight field corners. Maintenance is straightforward, and the parts are durable and long-lasting. The automated features, such as wrapping, save time and reduce manual labor. It’s fuel-efficient, which helps us manage costs during peak harvest times. Overall, it’s a reliable and efficient baler that meets our expectations.”

عميل من البرازيل:

“The 9YG-2.24D Round Baler has exceeded our expectations for handling tropical grass and hay. It processes crops quickly, creating compact bales that are easy to store. The machine works seamlessly even in humid weather conditions, which is vital for our farm. Its sturdy construction handles heavy use without any issues. The fuel efficiency is impressive, keeping our operating costs low. The automatic wrapping system saves time and ensures secure bales. The baler is easy to clean and maintain, which is important for long-term use. Customer support has been excellent whenever we needed guidance. It’s a great investment for Brazilian farms.”

عميل فرنسا:

“The 9YG-2.24D Round Baler is a fantastic addition to our farm. It handles alfalfa and hay with precision, producing bales that are uniform and tightly wrapped. The compact design makes it easy to maneuver in smaller fields. It operates quietly and efficiently, which is a bonus for our team. The build quality is exceptional, showing no wear even after months of intensive use. We appreciate the ease of operation and the clear instructions provided in the manual. The baler’s reliability has significantly reduced downtime during the harvest. It’s a high-quality machine that delivers excellent results consistently.”

عميل برازيلي:

“In Brazil’s demanding climate, the 9YG-2.24D Round Baler has proven to be incredibly reliable. It works efficiently with various types of forage, creating durable and neatly wrapped bales. The machine’s solid construction handles heavy fieldwork with ease. Its user-friendly controls reduce operator fatigue, even after long hours of use. Maintenance is simple, and replacement parts are easy to find locally. The baler’s performance in both wet and dry conditions is outstanding, ensuring productivity throughout the year. It’s a durable, efficient, and cost-effective solution for farms like ours. We couldn’t be happier with its performance.”

عميل من روسيا:

“The 9YG-2.24D Round Baler has been a reliable addition to our farm in Russia. It handles tough crop conditions and produces tightly packed bales that maintain their shape during storage. The machine performs well in extreme weather, from hot summers to cold winters. Its durable construction ensures long-term performance despite heavy use. The intuitive controls make it easy to operate, even for less experienced workers. Maintenance is simple, and spare parts are readily available. The baler’s efficiency has helped us save on fuel and labor costs. It’s a well-designed machine that we highly recommend to other farmers.”

معلومات إضافية

| حرره | Yjx |

|---|